How it Works

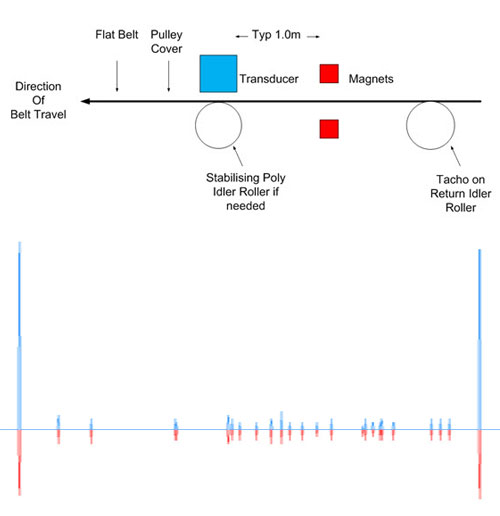

The Belt Scanner BSMF selectively magnetises the belt carcass as it passes the scanning location. Any discontinuity in a cord, even just cord filaments, gives rise to an external magnetic field (Magnetic Flux Leakage).

This magnetic field is then detected by the Transducer as the belt passes it.

The Transducer contains multiple pick-up devices dispersed across the belt.

The output from the Transducer is processed and stored internally. Damage sensitivity is better than one cord.

A tacho pulse train is derived from the Tachometric Device, which data is stored in a separate channel, giving longitudinal positional information.

The practical lateral resolution is a function of cord pitch, the number of pick-ups per metre of belt width and the working distance from the cords. For good lateral resolution it is essential that the pick-up devices are located as close as possible to the steel cords.

Disastrous Event Detection (DED)

The number of damaged cords at any belt cross section is monitored 24/7 and is referenced to a user-defined ‘Threshold’.

If this Threshold is violated a Command is delivered to the MEE and the HALT RELAY is energised. The HALT RELAY can be hard wired into the site SCADA environment via a dedicated Control Cable and may be used to stop the conveyor or alert operational personnel.

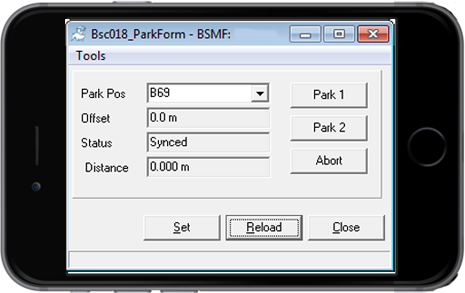

Programmed Parking (PP)

Using this feature in conjunction with a ‘belt map’, which lists the locations of the Splices and Events in the endless belt, it is possible to stop the conveyor automatically, with a ‘location of interest’ being parked in a maintenance area.

This can be achieved from a Laptop or PC running Belt Guard Boss software, and is connected to the device via a Site Network or Cellular Broadband service. This can also be achieved from the maintenance area using Citrix on a mobile phone, Tablet or similar device, running the appropriate App. Internet access is required.

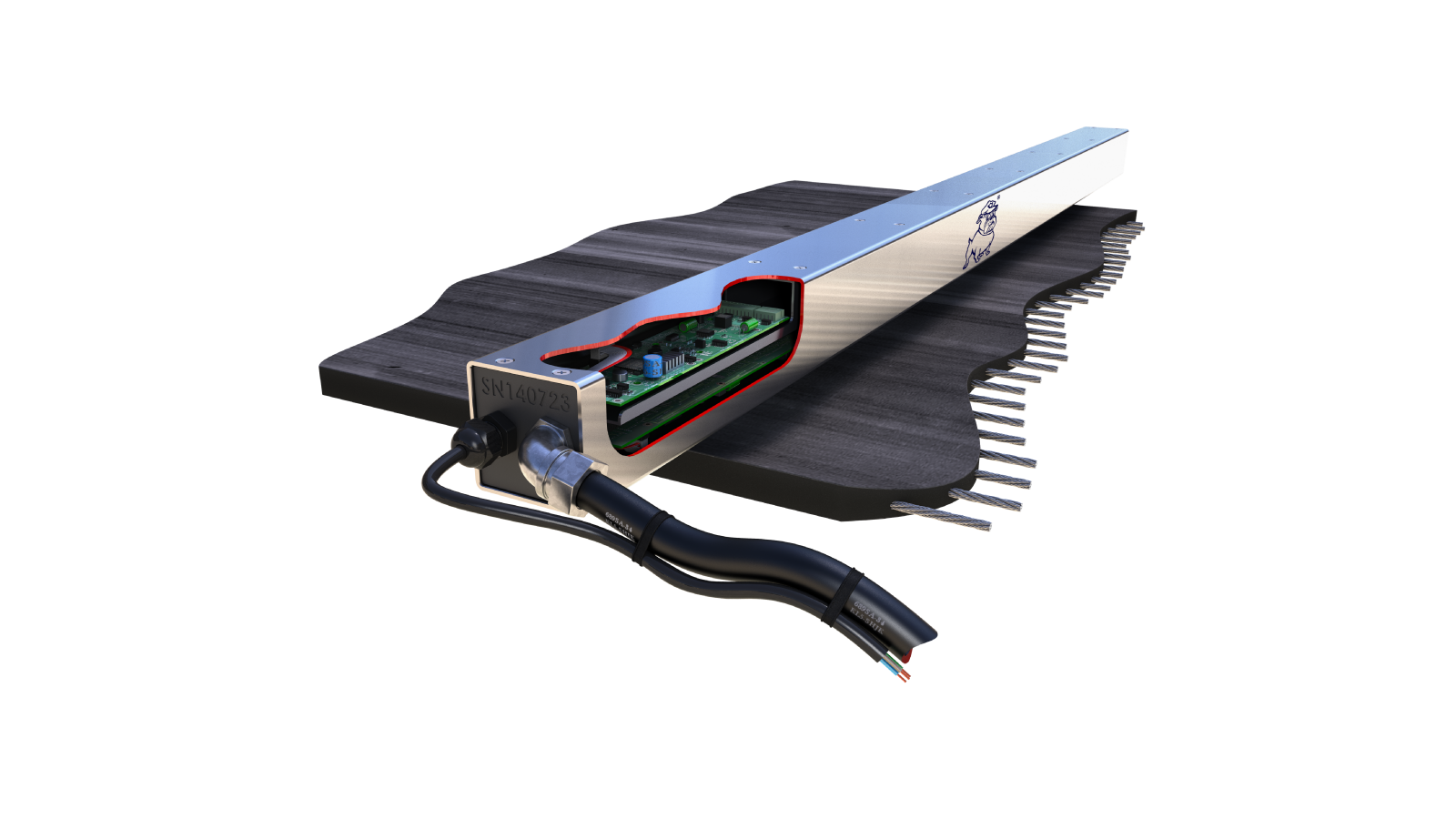

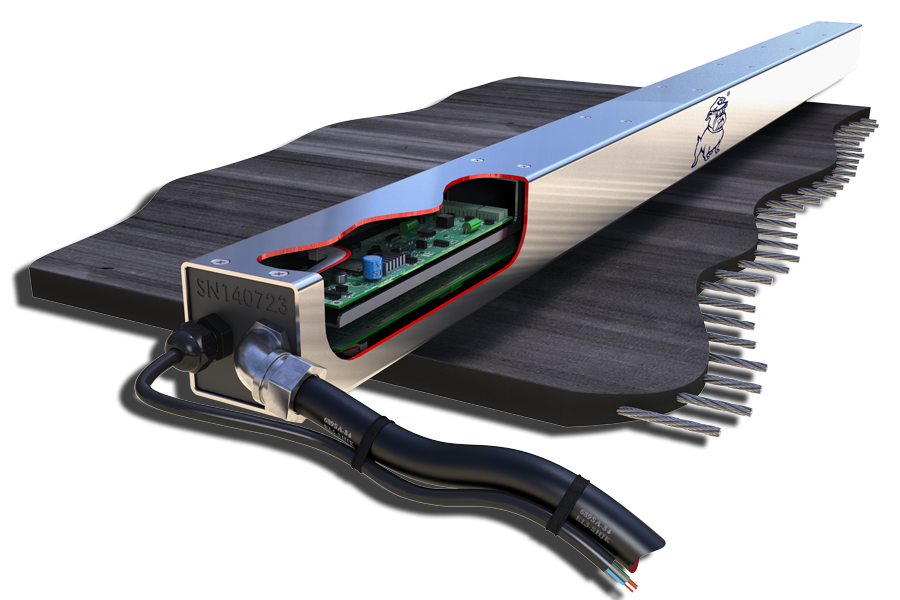

High Resolution Transducer

The Belt Scanner BSMF Hi-Resolution sensing device consists of a stainless steel Transducer fabricated to over-span the width of the target conveyor belt. This allows for belt wander.

The Transducer is able to detect;

- Broken cords

- Rusted / corroded cords

- Kinked cords (vertical plane)

- Fatigued cords (if cords have discontinuity in filaments consistent with plastic deformation and ductile failure)

- Missing cords and

- Splice anomalies, using magnetic signature comparison

Communications

The Main Electrical Enclosure (MEE) connects the system to a Site's SCADA and Network (optional). It is also a hub for other Belt Guard systems.

Technical support is provided via the Internet over a Site's LAN (VPN or limited network access) or via a dedicated Mobile Broadband modem. This allows the device to be accessed remotely for configuration and Log downloading. Software upgrades can be installed remotely, when available.

Connection to SCADA systems is only required for the Disastrous Event Detection and Programmed Parking features. Belt condition data is retrieved via a dedicated Ethernet Port.

Installation

Installation can be carried out by site personnel, under the supervision of a Beltscan product specialist.

Each Belt Scanner BSMF system consists primarily of: a) Transducer and Tachometer; b) Main Electrical Enclosure (MEE); c) Termination Enclosure and Flexible Steel Conduit; d) 2 x Belt Conditioning Heads.

Maintenance

The Belt Scanner BSMF equipment requires very little maintenance other than general housekeeping by ensuring the system is kept relatively free from product build-up etc.

Visual inspection should be carried out on a regular basis to confirm all mounts are secure and a light hose down on a regular basis is recommended.

The Transducer needs to be checked regularly. Build up of product on the Transducer will degrade the data quality.

Software

The Belt Scanner BSMF is a software-based device. All device configuration and operation is performed under Belt Guard Boss – Client software, which is supplied with the device.

Belt Guard Boss is accessible via a PC on the same network as the Scanner or via a range of platforms using a Citrix based solution. Access to the Internet is needed as well as sufficient rights to install the Citrix Receiver App on the relevant platform.

The optional ‘subscription-based’ Belt Analysis software is accessible from a range of platforms (Via Citrix) including; PCs, Macs, Linux Computers, Android phones, iPhones/iPads, Blackberrys and Windows Phones/Surface Tablets.

'Belt Analysis' is used to map the conveyor belt, asses levels of damage and to determine changes over time. Analysis and report generation can be done in-house, or outsourced to Beltscan for a monthly fee.

Technical Specifications

| Application | |

| Belt Type | Steel Cord |

| Belt Width | No Limit |

| Transducer | |

| Construction | Stainless Steel |

| Size (mm) | 80 x 80 x L (width of conveyor structure) |

| Net Weight | 8.75 kg / metre length* |

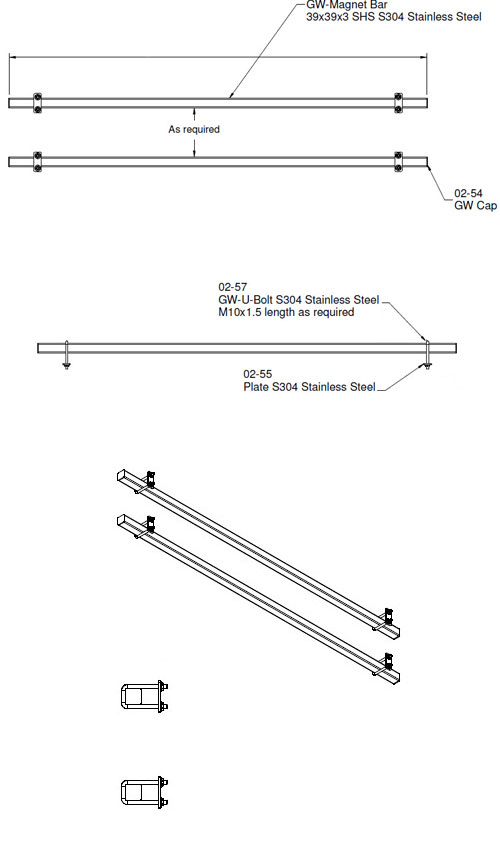

| Conditioning Head (each) | |

| Construction | Stainless Steel |

| Size (mm) | 39.0 (H) x 39.0 (W) x (L)* |

| Net Weight | 9 kg / metre length* |

| Main Electrical Enclosure | |

| Construction | 304 Grade Stainless Steel IP66 (NEMA4) |

| Size (mm) | 400 x 400 x 250 (No Weather Shields) |

| Electronics | |

| Power Supply | 110/220 VAC 60/50Hz or 24VDC |

| Power | ~10W |

| Communications | TCP/IP Ethernet and PLC Control Cable |

| DED / PP Output | Relay, Form C – 5A 240 VAC Contact Rating |

| Operating Temperature | -13 ~ 158°F(-25 ~ 70°C), 5 to 95% RH |

| Storage Temperature | -40 ~ 176°F(-40 ~ 80°C), 5 to 95% RH |

*Varies from system to system.