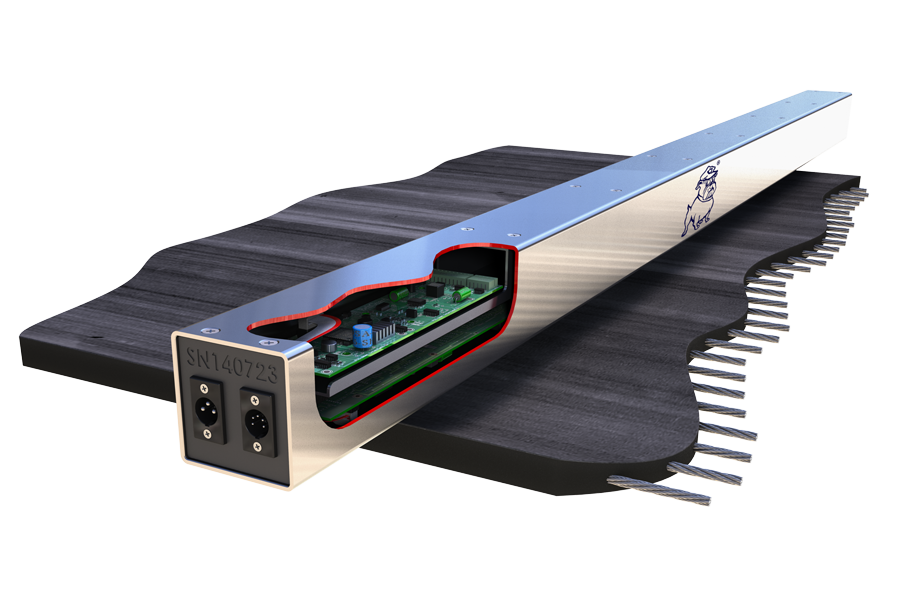

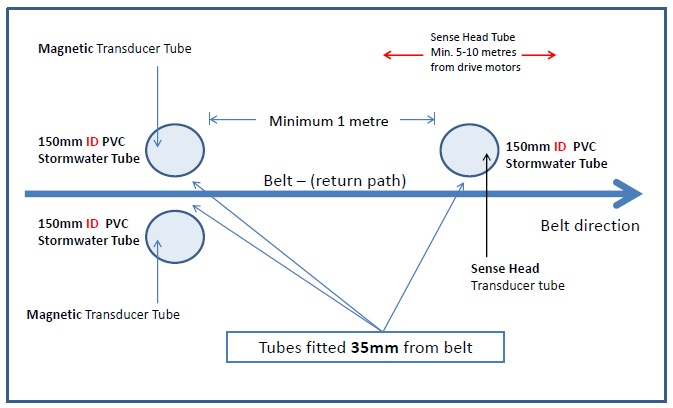

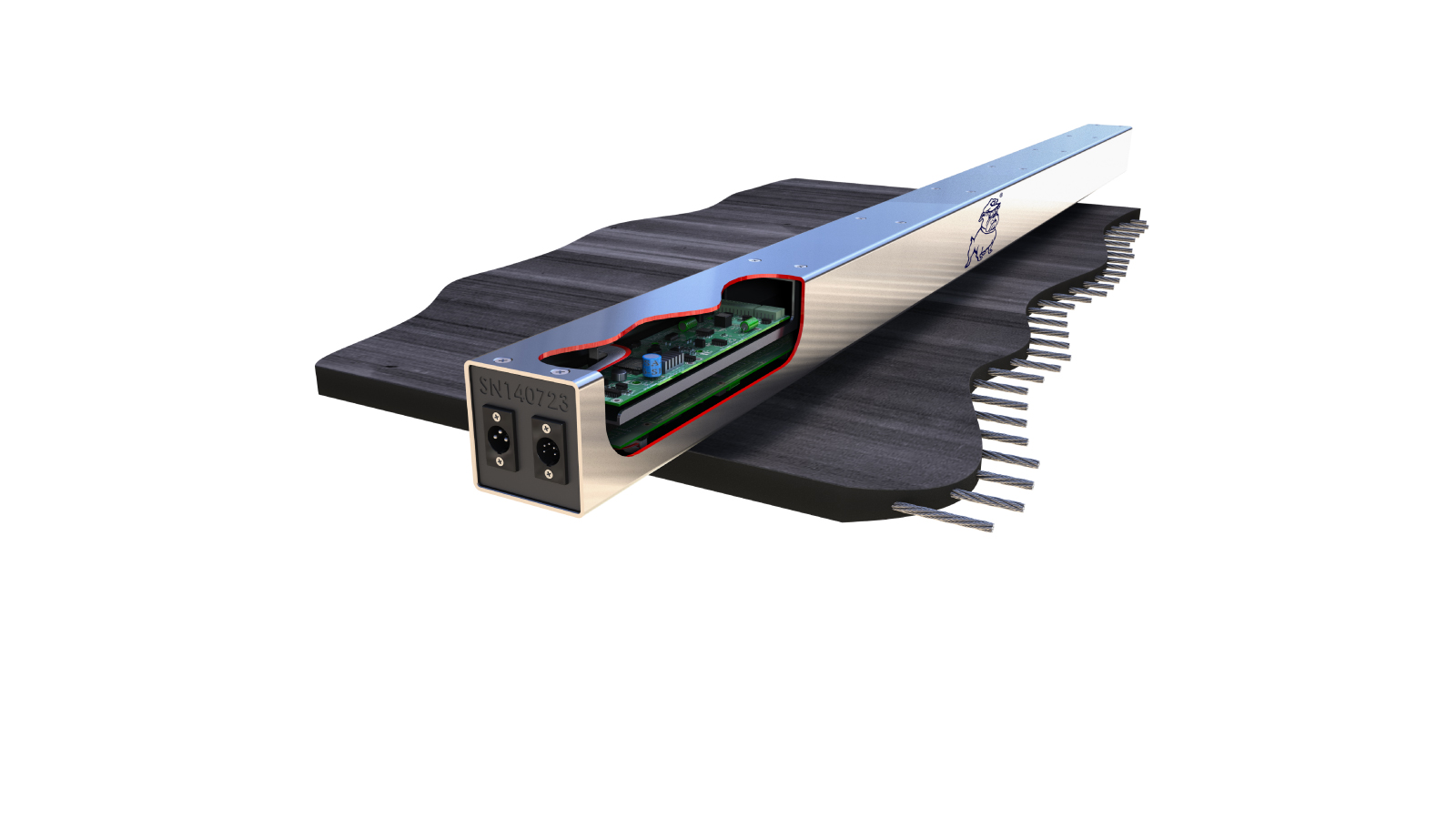

The belt carcass is selectively magnetised, by the Conditioning Heads, as it passes the scanning location. Any discontinuity in a cord, even just cord filaments, gives rise to an external magnetic field (Magnetic Flux Leakage). This magnetic field is then detected by the Transducer as the belt passes it. The Transducer contains multiple pick-up devices dispersed across the belt. The output from the Transducer is processed and stored internally. A tacho pulse train is derived from the Tachometric Device, which data is stored in a separate channel, giving longitudinal positional information. Cord damage sensitivity is better than one cord. The practical lateral resolution is a function of cord pitch, the number of pick-ups per metre of belt width and the working distance from the cords. For good lateral resolution it is essential that the pick-up devices are located as close as possible to the steel cords. The Belt Scanner Portable Hi-Resolution sensing device consists of a stainless steel Transducer fabricated to over-span the width of the largest target conveyor belt. This allows for belt wander. The Transducer detects;

1. Broken cords

2. Rusted / corroded cords

3. Kinked cords (vertical plane)

4. Fatigued cords (if cords have discontinuity in filaments consistent with plastic deformation and ductile failure)

5. Missing cords and

6. Splice anomalies, using magnetic signature comparison

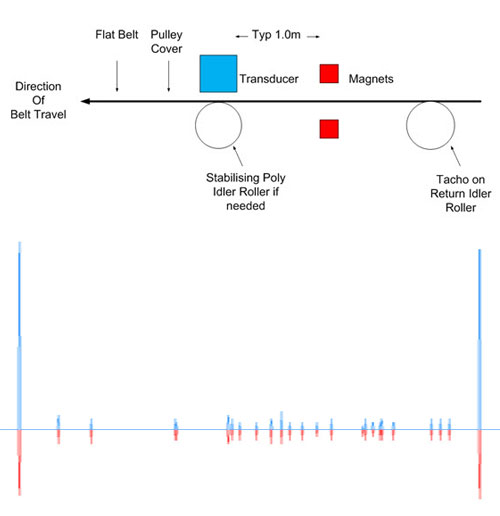

For manual scanning using the Belt Scanner Portable, the installation is temporary and varies from conveyor to conveyor. The Transducer must be located;

1. In a flat belt path (in one plane, not necessarily horizontal), where belt flap and droop are at a minimum.

2. Where no excessive rise and fall of the belt occurs during starting and stopping of the conveyor, particularly during emergency stops.

3. Away from electrically “noisy” locations, eg. adjacent to drive motors, electrical controllers and switch gear etc. Each Belt Scanner Portable system consists primarily of;

a) Transducer;

b) Tachometer, cable and magnets;

c) USB-RS485 Adapter, Software/Driver and Cables;

d) 2 x Conditioning Heads.

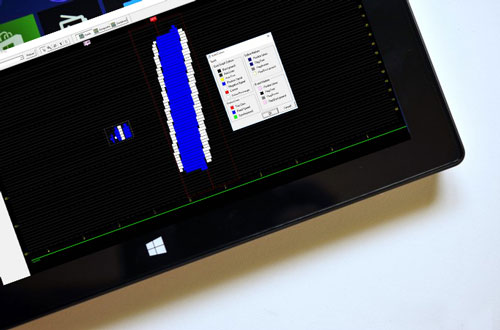

Unlike the Belt Scanner BSMF, the portable version does not include a Main Electrical Enclosure (MEE) and therefore does not have the Disastrous Event Detection (DED) or Programmed Parking (PP) features. Data is downloaded directly to a Windows based Laptop or Tablet via a powered 5v USB port. Software for Data Capture and basic Belt Analysis is provided with the device. The Belt Scanner Portable is a software-based device.

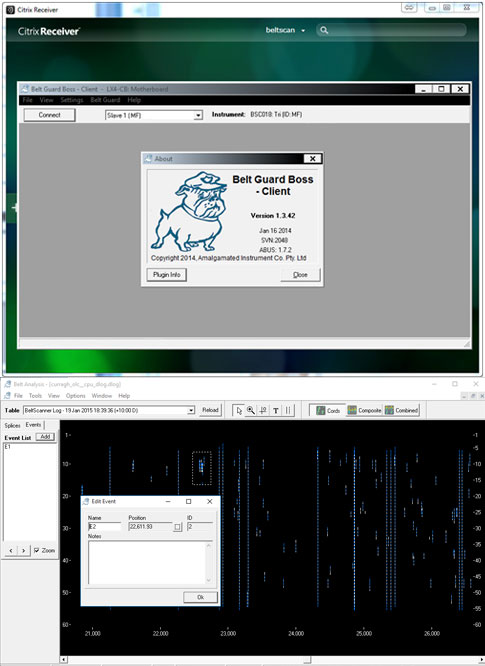

All device configuration and operation is performed under Belt Guard Boss – Client software, which is supplied with the device. Belt Guard Boss is accessible via a Windows based Tablet or Laptop with a powered 5v USB port. The optional ‘subscription-based’ Belt Analysis software is accessible from a range of platforms (via Citrix) including;

PCs, Macs, Linux Computers, Android phones, iPhones/iPads, Blackberrys and Windows Phones/Surface Tablets. 'Belt Analysis' is used to map the conveyor belt, assess levels of damage and to determine changes over time.

*Varies from system to system.

How it Works

High-Resolution Transducer

Installation

Communications

Software

Technical Specifications

Application

Belt Type

Steel Cord

Belt Width

No Limit

Transducer

Construction

Stainless Steel

Size (mm)

80 x 80 x L (width of conveyor structure)

Net Weight

8.75 kg / metre length*

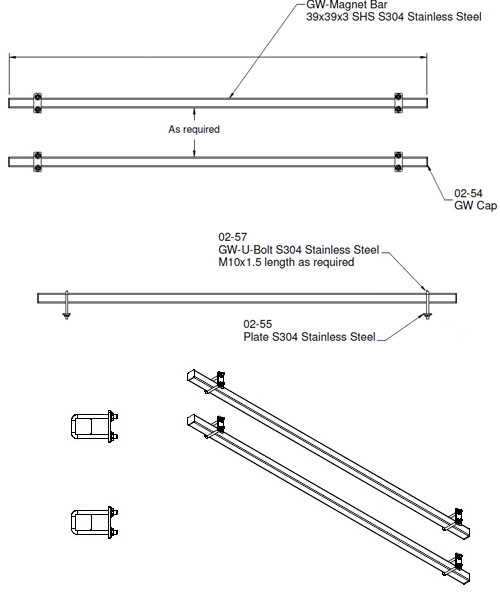

Conditioning Head (each)

Construction

Stainless Steel

Size (mm)

39.0 (H) x 39.0 (W) x (L)*

Net Weight

9 kg / metre length*

USB-RS485 Adapter

Construction

Encapsulated IP68

Size (mm)

135 (H) x 65 (W) x 45 (D)

Net Weight

1.3kg

-

Belt Scanner Portable Monitoring

Non-Contact Powered by 5v USB from laptop or tablet State-of-the-art analysis software