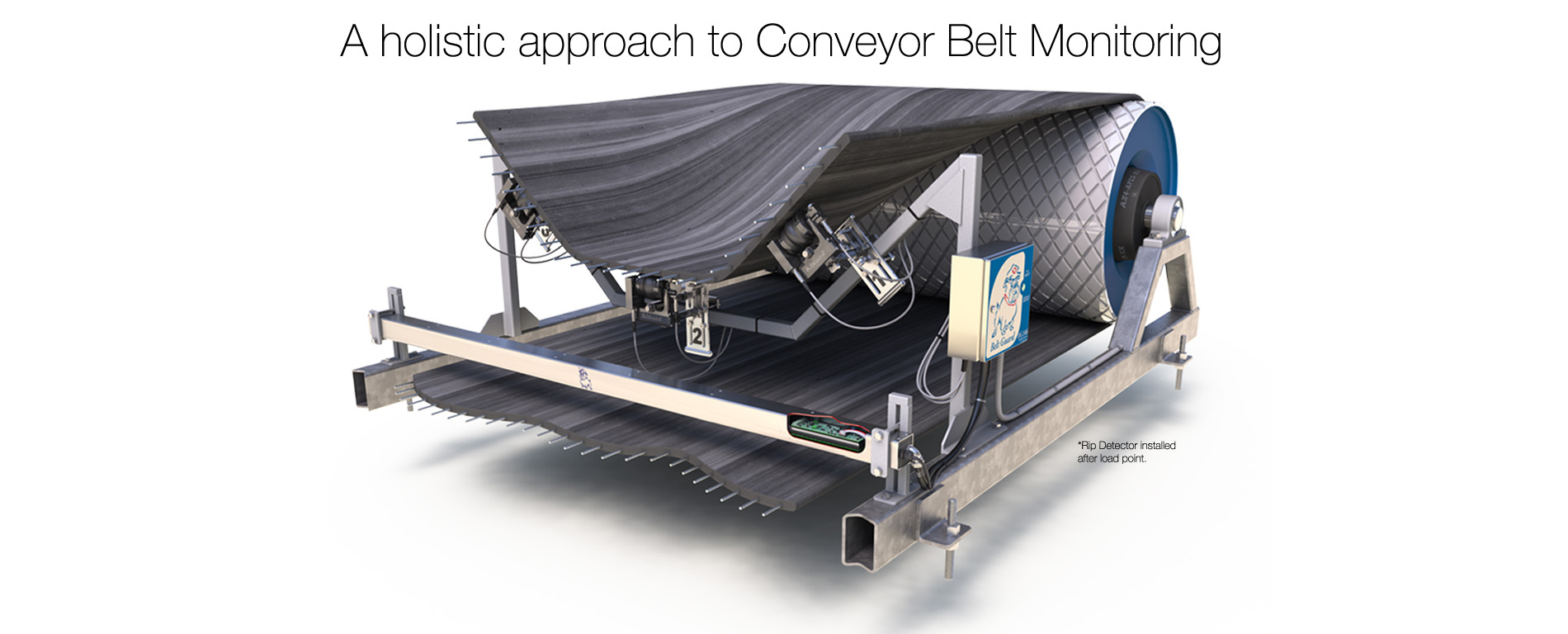

Shared Resources

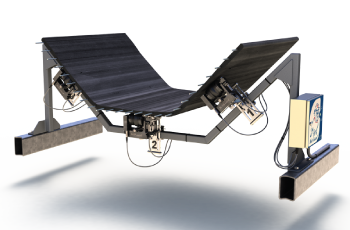

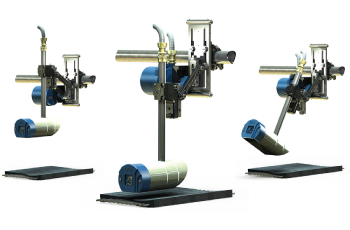

All Belt Guard systems are designed to share resources between each other. A single Main Electrical Enclosure (MEE) can be used to share communications and house system motherboards.

Optional accessories including; weather shields, Climate Control units and IP Surveillance camera equipment can also be consolidated.

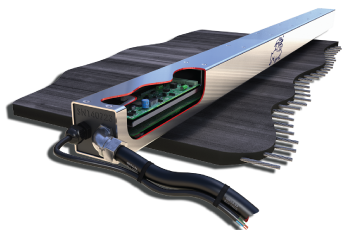

Shared Software Platform

Our Belt Guard Boss software is used by all devices for communication, configuration and reporting. A single executable can be used to connect to multiple devices at the same time through a wide range of platforms including; Windows, macOS, Android and iOS.

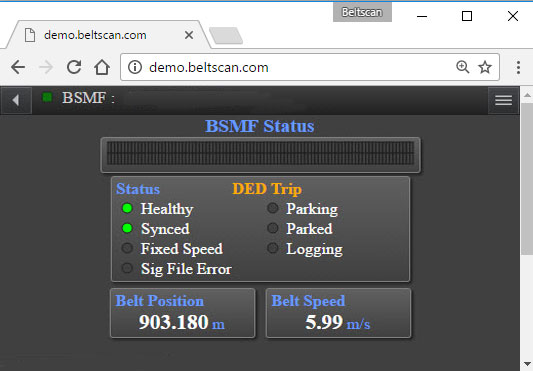

Online Availabilty

Each system contains networking capabilities to allow LAN connections to site or access via Mobile Broadband services. Our system boards are configured with built-in HTML5 web portals that allow remote access from any Internet enabled device like; PC's, tablets and mobiles. No other software is required.

With the appropriate credentials, a range of tasks can be performed, including; checking system health, initiating scans, bypassing equipment and even triggering belt stops and parking the conveyor at a desired maintenance location.